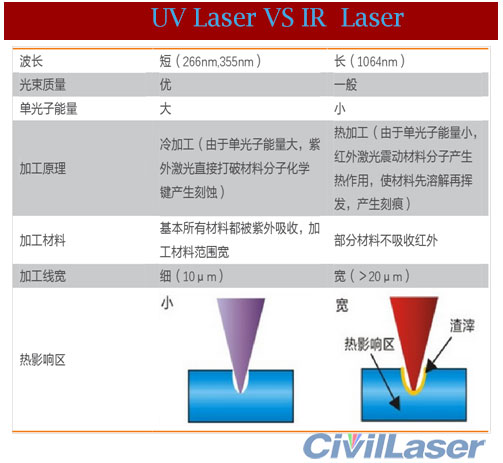

The output wavelength of the ultraviolet laser is below 0.4 μm, which is characterized by short wavelength, concentrated energy, and high resolution.

Infrared or visible light is usually processed by means of concentrated localized heating to melt or vaporize the material.

However, this heating can cause severe damage to the surrounding area, thus limiting edge strength and the ability to produce small, fine features.

Ultraviolet lasers are chemical bonds that directly destroy the atomic components of the connecting substance.

This process of separating matter into atoms is a “cold” process that does not produce heating to the periphery.

On the other hand, most materials can effectively absorb ultraviolet light, which can be used to process materials that cannot be processed by infrared and visible lasers.

Therefore, ultraviolet lasers have a great advantage in processing metal materials (especially surface treatment processes).

In addition, the UV laser adopts a cold-worked form, which generates low heat, and also has advantages in the processing and fine processing of brittle materials such as silicon, ceramics and glass.